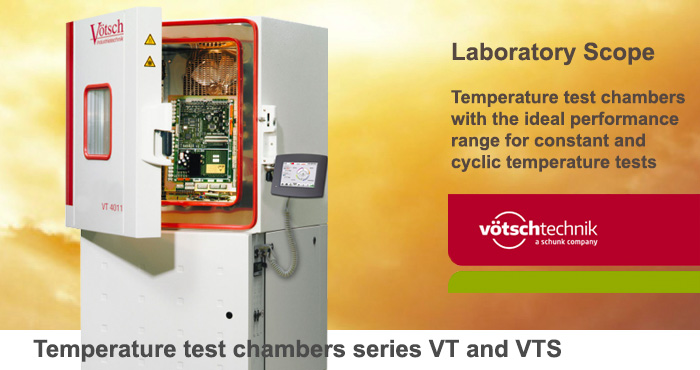

VT Temperature test chambers with the ideal class for laboratories

VT Series temperature test chambers with the ideal performance range for constant and cyclic temperature tests. The relation of external dimensions, test space volumes, efficiency and operating costs are excellent.

The temperature test chambers VT 4011 to VTS 7021-5 are especially designed for use in laboratories.

The relation of external dimensions, test space volumes, efficiency and operating costs are excellent.

All of these extremely compact systems offer a remarkable test space volume. Even the 110L system is capable of accommodating three 19" racks.

The system is equipped with an entry port NW 80mm for connecting supply/measuring lines to electronic components.

Rapid temperature cycles, high heat compensation and a low noise level make these systems highly favourable for use in laboratories.

Castors, provided as a standard feature, make these chambers highly mobile.

Performance for constant and changing temperature ranges from -40/-70°C to +180°C.

The chambers of series VT are ideal for laboratories, they are of a 1-phase design (230V AC).

In addition we offer the high performance VTS-series with temperature change rates to 10K/min.

The control and communication system provides the highest level of operating convenience, with the removable, menue-controlled colour touchpanel with graphics-capable display.

A powerful 32-bit control system forms the basis for monitoring and controlling of the test equipment. The series VT and VTS are equipped with the control system SIMPAC.

Extensive test programs can be easily and reliably created, safe-guarded and reactivated.

Main advantages

- Light-weight with high performance

- Small installation area

- Low power input/operating costs

- Easy operation with colour touchpanel

- Reliable also at high ambient temperatures

- Mains connection 230V (VT-series)

- Silent operation

- USB interface with recording function

- Remote control and remote monitoring via intranet or internet.

Standard equipment

- Colour touchpanel for comfortable input

- Microprocessor monitoring and control unit SIMPAC

- USB and ethernet interface

- Smooth test space walls

- Independent, adjustable temperature limiter t min/t max

- Adjustable software temperature limiter min./max.

- Air-cooled refrigeration unit, chloride-free

- Potential-free contact for switching-off of test specimens

- Calibration of 2 temperature values

- Entry port NW 80mm

- Mobile design

The most important options

- Software SIMPATI

- Digital I/O

- Analogue transducer card I/O

- Adjustable circulating air quantity

- Temperature measuring on test specimen

- Interface RS 232 - Interface converter RS 232, RS 422/485 or IEEE 488

- Interface RS 422/485 (Network card for test cabinet)

- Dehumidification during heating cycle (only VT-series)

- Compressed air dryer for dew point -30 °C unregulated

- GN2/compressed air connection

- Water-cooled refrigeration unit

- Lead-through pad

- Notch

- Additional insert shelves

- Additional entry ports

- Door with window & light

- Door with window & light and 2 handholes

- Low noise suppression

- Spatial WKD or DKD calibration

- Special voltages

The nice software

The SIMPATI control software (optional) enables you to use your systems even more effectively.

Operation of test systems becomes simple and time-saving. Evaluation and documenting of test cycles and the integration of special measuring data guarantees an improved standard.

SIMPATI is network-integrated offering remote operation from other PCs in your network. No special software is required – a standard Internet browser will be sufficient.

It's obvious that our system for controlling SIMPAC and the software SIMPATI fulfil the requirements of "21 CFR Part 11 Compliance".

Further information is available in the SIMPATI brochure.