Galaxy Halt-Hass System

The Galaxy HALT/HASS systems are integrated test chamber/vibration table packages. These chambers are outfitted with a liquid nitrogen (LN2) cooling systems. The vibration table is a six degree-of-freedom (6DoF) tri-axial pneumatic vibration table.

Galaxy – Advanced Product Reliability Testing

Weiss Technik’s Galaxy HALT/HASS systems are integrated test chamber with vibration.

The Galaxy system offers rapid thermal change rates, up to 70°C/min, using LN2. The cryogenic cooling system, with modulating valve and directed air flow to the product, provides the rapid thermal change rates needed to achieve maximum product stress. Additionally, these rates are accomplished with smaller space requirements, lower audible noise, no water requirements, and lower maintenance costs than a typical refrigeration system

Highlights:

- Multi-Directional Air Flow

- Full Table Access

- Universal Port

- Front & Rear Door Opening

A flexible solution for HALT/HASS vibration testing - with or without temperature – can also be provided by a moveable vibration table. This requires only a small footprint and reduced equipment.

HALT Testing

Highly Accelerated Life Test

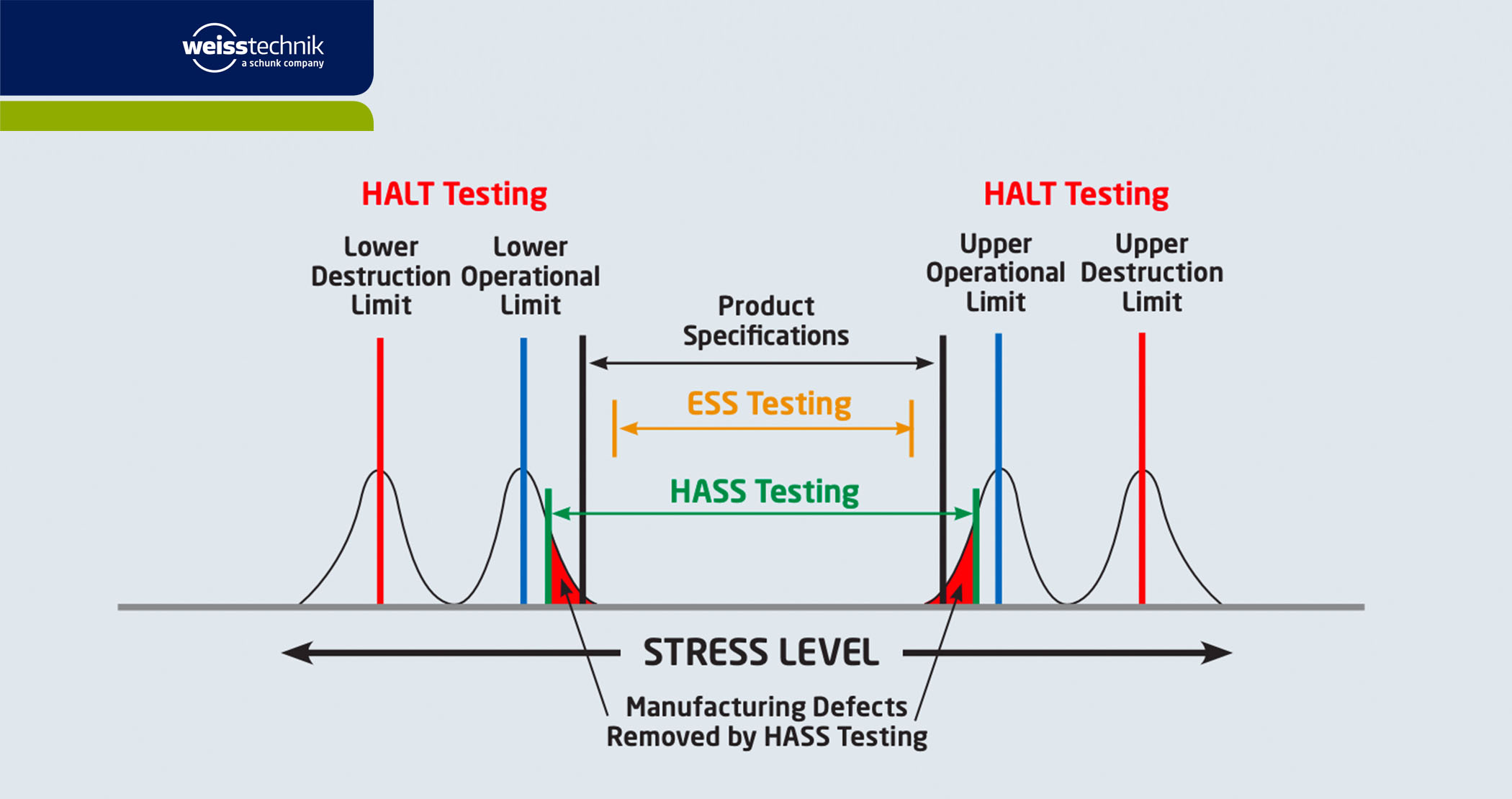

The goal of every manufacturing company is to bring a product of world-class quality to market in the shortest time, and at lower cost. There is even further incentive to improve field reliability and lower warranty claims. Many manufacturers use HALT and HASS testing to help them achieve these goals.

In the HALT process, the test sample is subjected to progressively higher stress levels, thermal dwells, rapid temperature transitions, vibration, and a combination of the two.

HASS Testing

Highly Accelerated Stress Screen

HASS is a post-production process that can be performed on 100% of products or a partial sample of units (HASA – Highly Accelerated Stress Audit)

The main goal of HASS is to precipitate and detect hidden or latent failures. It is used to verify that no new “weak link” has crept in to the product. Ultimately, its purpose is to prevent flawed units from reaching the end-user/customer.

Typically, HASS stress levels are less than those used in HALT; however, they are generally more severe than anticipated in actual service. The goal is to use enough stress to find fault – but not enough to remove a significant amount of the product’s life.

Random Vibration Table

The integrated vibration table provides acceleration, utilizing quasi-random, six-degree-of-freedom, vibration acceleration in the frequency range 0 to 10kHz. The table can deliver axis-specific vibration levels up to 100gRMS.

Table acceleration levels can be mounted and controlled via a tri-axial accelerometer block, or single Z-axis control.

Benefits of HALT/HASS include:

- Precipitates hidden or latent failures caused by poor workmanship or manufacturing processes.

- Verifies integrity of mechanical interconnects

- Prevents flawed units from reaching the end-user

- Detects changes in components and processes

- Decreases warranty and field service costs

- Increased customer satisfaction