Stress screening systems WTS3/WKS3

The Environmental Stress Screening (ESS) systems produced by Weiss Umwelttechnik establish new standards for easy operation, high performance and good equipment.

With high speed to top quality – WTS3/WKS3 Test Chambers

Reliable test results by means of reproducible environmental conditions

Characteristics, function and service life of systems or components are influenced by varying thermal and climatic conditions during transport, storage and use. For this reason, tests have to be carried out in order to safeguard and optimise the quality of the product.

The stress screening systems produced by Weiss Umwelttechnik set standards with regard to ease of operation, performance and equipment.

Weiss Umwelttechnik GmbH is one of the leading manufacturers of test devices and systems for environmental simulation worldwide.

The product range comprises test systems of all test chamber volumes for temperature and climatic testing, simulation of exposure to weather, temperature shock, corrosion and long-time testing – in research, development, quality control and production.

Walk-in systems and in-line plants are designed, produced and installed in accordance with customer specifications.

An excellent after-sales service ensures optimum support for our customers and a high degree of operational safety of our systems.

Safety first

Reliable testing to guarantee safety

High product reliability is a basic requirement for today’s competitive market and is often the only difference between the various manufacturers.

The reliability of electronic products can be substantially improved by the use of environmental stress screening (ESS) techniques to minimize the risk of errors and failures of products and simultaneously improve the reputation of a company.

What is ESS?

The test

During the ESS test, the products are subject to precisely defined stress so that defects in components and PCBs can be detected before leaving the manufacturer’s plant. Detecting weak points con-siderably improves the robustness of the products. Unreliable systems are filtered out before they reach the customers.

Each product requires a specially adapted ESS technique.

The advantages of ESS

Improvement of product reliability. The products do not simply function, they operate correctly for a long period of time.

The quality itself is substantially improved, customer satisfaction increases and the sale of reliable products likewise. Reliable products ensure that the reputation of the manufacturer on the market remains a good one.

ESS means reduced costs

as product failures do not occur during the warranty period when they are already in the possession of the customer.

ESS reduces the risks which can occur in products due to components or processes and there is less risk involved when a new product or new technology is introduced.

ESS means quick “feedback”. Construction or process problems can be detected more rapidly which means a quicker “learning curve”. Also “feed-back” is obtained directly from in-house quality assurance and not via the customer.

ESS Methods

Mode and effects

In practice, the following ESS methods have prevailed:

- Temperature stress

- Vibration stress

- Humidity stress in conjunction with electrical stress

Our stress screening test chamber series was specially designed for temperature stress.

The WKS 3 series of climatic test chambers is available for humidity stress.

Environmental stress screening on PCBs (or other products) is achieved by thermal stress with quickly changing temperatures.

ESS is the most effective method of detecting poor soldering joints and SMD processes as well as manufacturing errors before delivery.

Typical ESS profiles contain a thermal change with 5 ... 15K/min over a wide difference in temperature.

The periodic or constant switching of the boards during the thermal cycle can increase the detection of errors.

The above-mentioned results are achieved in special ESS chambers because the heating and cooling capacity as well as the amount of circulating air is considerably higher than that of a conventional test chamber.

High amounts of circulating air improve the heat transition and ensure that the specimens and/or boards are homogeneously stressed.

Weiss Umwelttechnik has developed a range of systems especially for this purpose which does more than justice to the above-mentioned requirements.

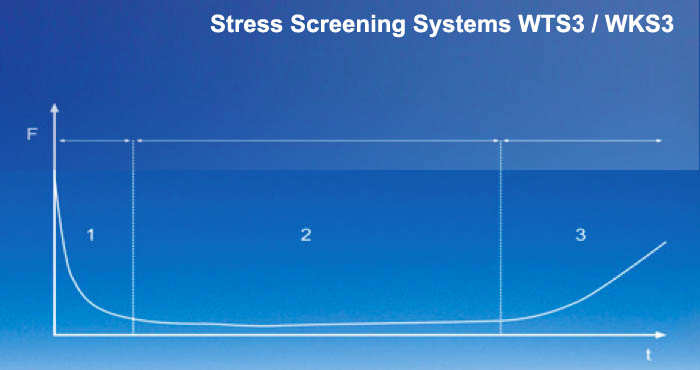

Service life curve of electronic components.

ESS means that errors which normally occur during the usage phase occur in the production phase

F = error / t = time

/ 1 = early failures / 2 = usage phase / 3 = wear phase

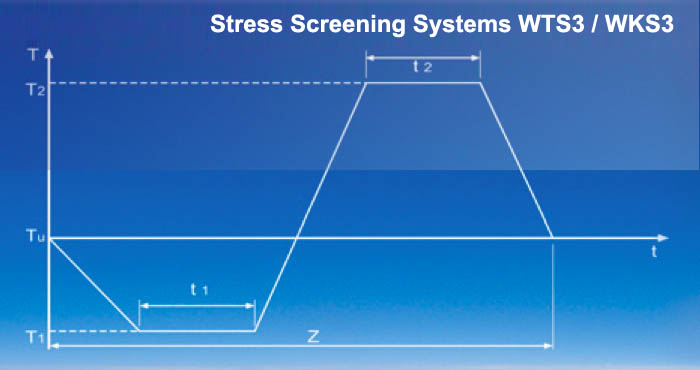

Temperature shock cycling test as per IEC 60068-2-14, Test Nb

T = temperature / T1 = low temperature / T2 = high temperature / Tu = ambient temperature / Z = cycle / t = time

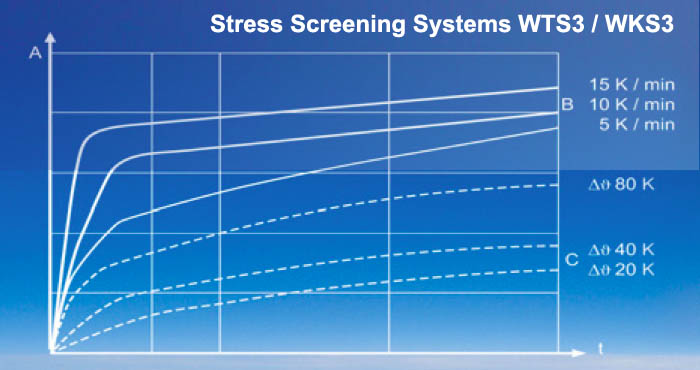

Effectiveness of thermal cycles and high temperature storage for preconditioning of circuit boards

A = effectiveness / B = thermal cycles / C = high temperature storage / t = time / Δυ= temperature increase to max. working temperature

Convincing Technology

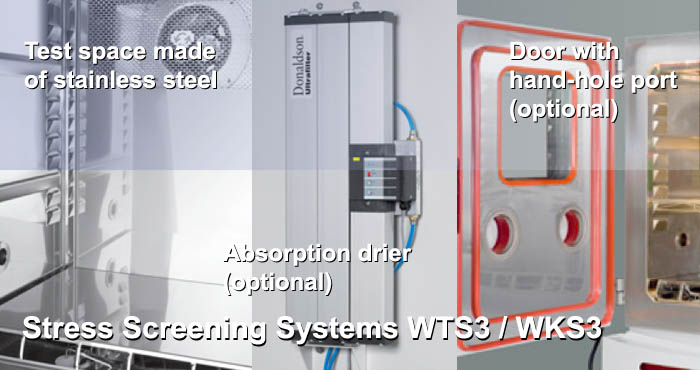

The stress screening systems of the series WTS3/WKS3

The test systems based on the well- tried modules of the WTS3 and WKS3 series with increased power for heating, cooling and circulating air and test chamber volumes of 190 to 1.540 litres are capable of meeting virtually all requirements.

The WKS3 series also complies with customary climatic test standards.

Perfection in performance, equipment and design

- Operation, monitoring and documentation of the test system with the control and monitoring system SIMPAC

- 8’’ TFT-colour touch screen display with simple, menu-guided user interfaces as a convenient interface with the operator

- Lighted CONTROLPAD for displaying the operating mode and the actual values in the front of the test chamber (if the system is equipped with 8’’ and 12’’ TFT-colour touch screen display)

- USB and Ethernet interface

- Networking with other test systems possible

- Remote control and remote monitoring possible via intranet or internet

- Integrated recording of measurement data for a complete documentation of the test procedure

- High-precision temperature and climate conditions due to autoadaptive control

- Integrated service information system

- Performance optimised climate and temperature conditioning system creates power reserves for your tests

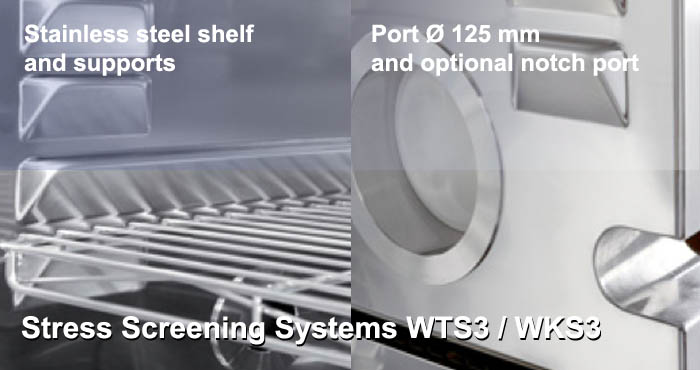

- Stainless steel ports (approx. Ø 50 and 125mm) for inserting the supply lines – even in the standard version of the equipment

- Self-cleaning humidity sensor with considerable increase of the service life

- Optimised guidance of the air and temperature distribution – better than ±1.5K spatially guaranteed

- For very safe operation the test chambers are designed for extreme environmental conditions

- Compliance with demanding state-of-the-art test standards by means of increased humidification output

- Large water container easily accessible

- Low noise level

- Standard humidity bath flushing to prevent contamination of humidification water

- Long-time testing +85°C / 85% r.h. – our WK3 climate test chambers are the solution

- Factory calibration of temperature and humidity values is part of our standard

- Supply connections located in a central and protected position in the rear part of the device

Design features and functional principle

Perfectly manufactured

- The external housing is made of corrosion-resistant, galvanised steel sheet and solvent-free powder coated

- The stainless steel test space is welded vapour-tight

- Its environmentally friendly insulation guarantees the best possible insulation values and, hence, the lowest possible operating costs

- Even in the standard version of the equipment all sizes are equipped with two standard stainless steel ports (approx. Ø50 and 125mm). They can be used for inserting measurement and control cables, other supply connections or additional equipment

Safe design

- The test chambers are equipped with an adjustable safety cut-out against high and low temperatures (test specimen protection with separate sensor) according to EN 60159-2 (1993)

- Any safety alarm is issued visually as well as acoustically

- The door latch ensures an optimum closing pressure while ensuring protection against excess pressure at the same time

- The large observation window which is available as an option allows an optimum view of the test space and it is equipped with multiple glazing and heated in order to prevent the formation of condensate

- A potential-free contact is available on the test chamber

- Every electrical functional circuit is equipped with its own safety facility which shuts down the functional circuit affected or the entire test chamber in case of a malfunction

- The electrical system complies with the approved state of the art in the field, the safety regulation “Electrical Systems and Facilities” (BGV A3) as well as with the relevant VDE regulations

- All test chambers fulfil the EMC, low-voltage and machinery directive

- The hermetic refrigeration circuits operate with environmentally friendly refrigerants (CFC-free)

Ready for use

A quality inspection of every test unit is effected before delivery. They are designed ready for plug-in and are directly ready for use. There is no need for an assembly on site.

Standard version

- Digital measuring and control system SIMPAC

- 8’’ TFT-colour touch screen display

- CONTROLPAD for displaying of temperature values, lighting, start/stop, etc. on the front panel of the device

- Auto-adaptive control system

- Ethernet and USB interface

- Refrigeration unit, water-cooled

- Stainless steel ports approx. Ø 50mm and 125mm in the left and right side panel

- Safety cut-out against high and low temperatures (protection of test specimen as per EN 60519-2 (1993) adjustable, with separate sensor

- Insertion rack (stainless steel)

- Adjustable and vibration absorbing feet

- 4 digital outputs (24 V-DC), 4 digital inputs (24 V-DC)

- Potential-free contact for specimen disconnection

- 2 temperature values are calibrated (+23°C and +80°C)

Additional equipment for WKS3 series

- Integrated limit value monitoring system for humidity

- Psychrometric humidity measurement with automatically wetted, self-cleaning sensor

- Large water tank, easily accessible

- Automatic feeding in of additional water without interruption of operation

- Display of the humidity values at the CONTROLPAD

- Humidity bath flushing for cleaning of the humidifier water

- 2 climate values are calibrated (+23°C / 50% r.h. and +95°C / 50% r.h.)

Options

- 3.5’’ TFT-colour touch screen display (without CONTROLPAD)

- SIMPATI software package for Windows, as off XP

- Test space door with observation window including optimised test space lighting

- Door with hand-hole port

- Door hinged on right side

- Mobile installation by means of moveable version

- Speed-controllable fan in order to vary the circulating air volume flow

- Fresh air purge facility in order to keep the air in the test chamber clean

- Shelves for optimum use of the test space

- Stainless steel ports approx. Ø50, 80 and125mm for connection of the test specimens

- Temperature measurement on the test specimen

- Interface RS 232 C and further interfaces upon request

- Other voltages and frequencies

- Digital I/O, 4 inputs and 4 outputs

- Calibration in deviation to the standard

- Additional calibration (WKD – Factory Calibration and DKD – German Calibration Service)

- Reinforced test chamber floor up to 150kg (200kg from 600 l)

- Floor for heavy loads up to 500kg (only available as of 600 l)

- Flat notches or notches for the fixed placement of connected test specimens

- Ports in the area of the roof

- Upgradeable for special test regulations (automotive, photo- voltaic, etc.)

Additional equipment for WKS3 series of models

- Independent capacitive humidity sensor (temperature and humidity measurement)

- Humidity control via capacitive humidity measuring system

- Pressure-resistant demineralisation cartridge

- Dewpoint extension in climate working range controlled down to -20°C, and uncontrolled down to -30°C)

Further options/special accessories, tailor-made for your special requirements, upon request.

Control System

Control and program control with the digital measurement and control system SIMPAC

Comfortable operation

The units WTS3 and WKS3 are equipped with an 8’’ TFT-colour touch screen display. In addition, an easily readable CONTROLPAD is integrated into the door, started and stopped through test cycles, and actual values for temperature and humidity can be easily read. Simple, menue-guided user interfaces are the convenient interface with the operator. There is no need for programming knowledge.

With the integrated process visualisation, the device function is explained in a way that is easy to understand.

Numerous ways of networking

Control is governed by the 32-bit- I/O system with integrated soft-PLC. A webserver can place test and diagnostic information into the intranet via Ethernet, if desired. The devices can be reached and operated from almost any place in the world. All it takes is network access to the device’s webserver in the intranet or in the internet, if activated accordingly.

Standard interfaces are Ethernet 100/10 megabit and USB for external storage of measurement data on a USB stick. Four potential-free outputs and four inputs (24 V-DC) are available for test specimen control.

Fully developed software

With the optionally available SIMPATI software, you have the optimal system for operation and control of the test system. The software not only permits evaluation and documentation of the test sequences, but also allows problem-free integration of the system into a PC network. Archiving of the data and parameters is always ensured with the SIMPATI software.

Alternatively equipped with 3.5’’ TFT-colour touch screen display

As an option, the device can be equipped with a 3.5’’ TFT-colour touch screen display (320 x 240 px). The display is integrated in the door in place of the CONTROLPAD and is delivered with the SIMPATI program tool for simple control of the test chamber. The 3.5’’ display thus ensures optimal operation of the system at a favourable price.