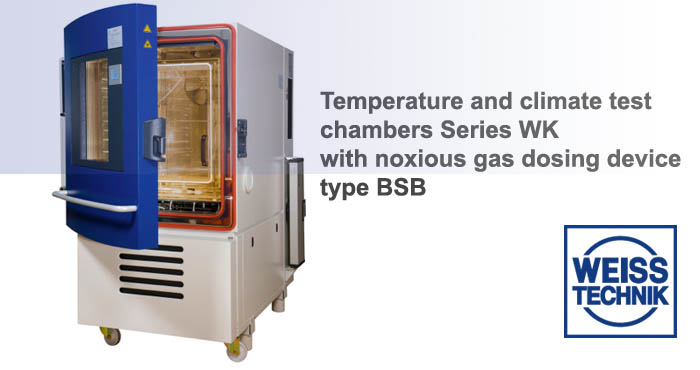

BSB – Climate test chambers for noxious gas test

To analyse corrosion processes impact of noxious gases systematically, test systems are necessary, in which the corrosion-promoting noxious gas concentrations and climates can be adjusted according to the standards.

Corrosive gases in the atmosphere (noxious gases) cause damages to material, components, devices and constructions.

To analyse these corrosion processes systematically, test systems are necessary, in which the corrosion-promoting noxious gas concentrations and climates can be adjusted according to the standards.

Application

- Single-gas tests

- Series of single-gas tests

- Mixed gas tests

The noxious gas test chamber can be removed and inserted! The system can be used as climate test chamber without the inner test chamber!

Additional applications

- Inner test chamber made of plexiglass or polyvinylidene fluoride (PVDF)

- Dosage pump (PTFE design) or mass flow controller

- Low pressure control in the noxious gas chamber

- Dilution of air containing noxious gas is necessary.

Main advantage

- Interruption of noxious gas supply in case of erroneous opening of chamber door

- Powerful and uniform temperature/air conditioning

- High temperature constancies by jacket air temperature conditioning

- Exactly adjustable test parameters and therefore highest reproducibility

- Aerosol-free humidification system provides „natural conditions“

- Easy removal of the inner test chamber

Technical specification

- Temperature range Acryl +15 ... +45°C (PVDF +15 ... +80°C)

- Humidity range 40 ... 75% r.h.

- Airflow adjustable between 0,5 and 4 m3/h

- Flow rate noxious gas adjustable between 1 and 250 ml/h

- Control system: Controller Board SIMPAC with Color Touch Panel