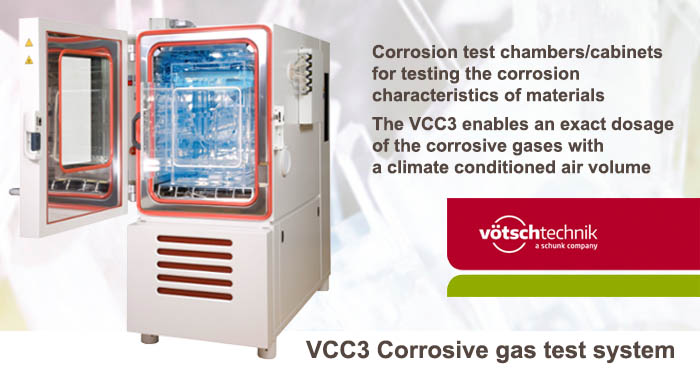

VCC3 test chambers for testing the corrosion characteristics of materials

To prove the resistance of the technical products to corrosive gases, Vötsch Technik developed the corrosion test chambers and cabinets series VCC3.

The VCC3 enables an exact dosage of the corrosive gases with a climate conditioned air volume. The main constituents of the corrosive, atmospheric trace elements are: sulfur dioxide (SO2), nitrogen oxide (NOx), hydrogen sulphide (H2S) and chlorine gas (CL2).

Features corrosive gas test system

- Gas dosing with thermal mass flow controller, concentration ranges from ppb to ppm

- Inner test cabinet with connection for gas sampling and entry port NW 50mm

- Air exchange rate in inner test cabinet can be set between one and four per hour

- Door with window included in basic equipment

- Specimen can be observed (inner test cabinet is made of acrylic glass (PMMA))

- Up to four gasses can be dosed simultaneously

- Inner test cabinet, shelf and door are made of acrylic glass

- Pressure monitoring between inner test cabinet and outside as a safety feature

- Compliance with test standards such as IEC 60068-2-60, IEC 60068-2-42/43, ISO 21207 and others

Test gases

- H2S

- SO2

- Cl2 with carrier gas N2 (nitrogen)

- NO2, with carrier gas synthetic air

- Other test gases on request

Standard version climate test cabinet

The basic unit consists of a test system of series Climate 3000 with 340, 600 and 1000 liters.

Standard version corrosive gas system

Cabinet extension (firmly mounted at the left side of the cabinet) including

- 1 gas dosing line with thermal mass flow controller and feeding line leading into the gas container

- Gas distribution system

- Purging gas line

- Air change system

- Pressure guide

1 auxiliary cabinet made of PMMA (120l, 270l, 380l) including

- Support grid of PMMA

- Sample gas connection

- Entry port at the right side, Ø 50mm

- Door made of PMMA

- Commissioning, functional test and test run in our company